Industrial scrubbers are an appliance for washing and removing stacked pollutants from floor surfaces. Thanks to the use of fully automated systems, these devices have a high speed of cleaning and improve the quality of washing. These devices use brush and water spraying systems to wash and remove contaminants that are accumulated on floor surfaces. Separate tanks for clean water and dirty water are other main parts of the scrubber device. This makes it easy to use clean water during washing operations. The sucker system is another key part of the industrial scrubber dryer that is responsible for collecting and transporting dirty water and liquids into a dirty water tank.

Scrubber equipment

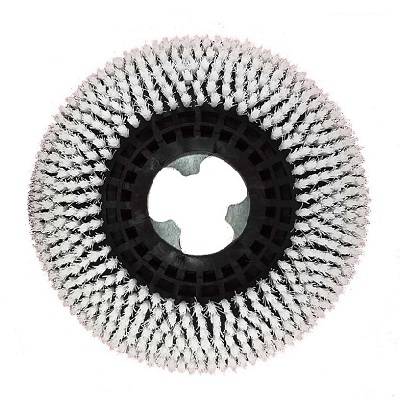

Scrubbers like any other mechanized machine, to provide continuous operation and to meet the needs of cleaning the various environments, need to use specialized equipment that is appropriate to the type of pollutants and the surfaces. The equipment consumed by these devices is worn out and in need of replacement over time and continuously. In addition, due to the type of pollutants and also the compatibility with the flooring, replacement parts are also required. The use of appropriate parts and equipment, while maintaining the functionality of the device at the highest possible level, also increases the life span of the floor and protects the floor against damage and scratches caused by the use of worn and inadequate equipment. The brushes, pads, batteries, and rubber tires can be mentioned, as the replaceable equipment of the device.

Advantages of using auxiliary equipment

The accessories of the scrubber are not limited to consumable parts and also include detergents. Considering that the use of new and suitable equipment with flooring has an important effect on prolonging the life of the device and protecting the flooring, the use of detergent can also facilitate the washing, in particular the removal of greasy and oily contaminants.