معرفی و کاربرد انواع نازل پاشش واترجت صنعتی در بهبود عملکرد نظافتی

کارایی بالای دستگاه های واترجت صنعتی در نظافت اماکن تجاری و صنعتی موجب افزایش کاربری آنها در بخش های خانگی گردیده است. توجه به ویژگی های پمپ و نازل های پاشش به عنوان اصلی ترین عامل در جهت دهی به پاشش آب پر فشار، از جمله تجهیزات جانبی کارواش صنعتی و عوامل اصلی در انتخاب دستگاه کارواش خانگی یا صنعتی می باشد. عدم انتخاب نازل کارواش صنعتی مناسب علاوه بر افت فشار کاری و کاهش دبی می تواند به سطوح هدف نیز آسیب وارد نماید. در ادامه این مقاله به بررسی تاثیر نازل در عملکرد بهینه دستگاه کارواش صنعتی خواهیم پرداخت.

فرآیند شستشو با واترجت صنعتی

واترجت صنعتی از جمله دستگاه های پر کاربرد در حزوه نظافت صنعتی می باشد. این دستگاه با اعمال آب پرفشار آلودگی ها را از روی سطوح از بین می برد. آب پر فشار خروجی از این دستگاه بواسطه یک پمپ فشار قوی ایجاد می گردد. پمپ فشار قوی با افزایش فشار آب ورودی به دستگاه، باعث افزایش چشم گیر قدرت نظافت می شود. شستشوی انواع سطوح شامل سطوح کف، سطح خودرو، تجهیزات و قطعات مقاوم در برابر آب با استفاده از این دستگاه نظافتی قابل انجام است.

واترجت ها از بخش های دیگری مانند لنس، نازل، شلنگ فشار قوی و موتور تشکیل شده است. برای شروع فرآیند شستشوی سطح با واترجت صنعتی ابتدا باید یک منبع آب مانند شیر آب پیدا کنید. سپس با استفاده از یک شلنگ منبع را به دستگاه وصل کنید. آب ورودی به دستگاه در ابتدا فیلتر شده و سپس به پمپ می رسد. پمپ فشار قوی وظیفه دارد تا آب را با توجه به میزان تعیین شده به فشار های بالا برساند. آب پرفشار در هر لحظه از پمپ خارج شده به سمت شلنگ فشار قوی و لنس و نازل می رود. استفاده از انواع تجهیزات جانبی کارواش صنعتی مانند نازل تعیین می کند که آب به چه صورت از دستگاه خارج شود. انواع نازل کارواش صنعتی در مدل های متنوع از زاویه پاشش صفر تا حدود ۶۰ درجه قابل نصب بر روی دستگاه است.

اگر در انتخاب نازل اشتباه کنید و از نازلی استفاده نمایید که فشار زیادی بر سطح وارد نماید، میتواند آسیب های زیادی بر رنگ بدنه خودرو یا خراب کردن سطح چوب و تخریب دیوار های آجری و سیمانی بر جای گذارد. گاهی آزمون و خطا، در انتخاب انواع نازل کارواش صنعتی راهکار مناسبی به نظر میرسد. با این حال بهتر است قبل از شروع کار، آشنایی نسبت به نوع کارآیی نازل ها و انواع آنها داشته باشید.

عملکرد نازل واترجت صنعتی با افزایش فشار آب چگونه است؟

به منظور درک بهتر عملکرد تجهیزات جانبی کارواش صنعتی مانند نازل واترجت صنعتی ، شلنگ آبی را تصور کنید. محدود کردن دهانه خروجی شلنگ با دست موجب افزایش فشار آب می شود. کاهش سطح مقطع خروجی در کنار فشار ثابت منبع موجب افزایش در قدرت و فشار آب خروجی از دستگاه واترجت صنعتی می گردد. عملکرد ناز ل ها نیز دقیقا مشابه همین مثال می باشد. نازل واتر جت صنعتی با محدود کردن دهانه خروجی آب، فشار تولید شده توسط پمپ را متمرکز نموده و موجب افزایش فشار، قدرت و سرعت پاشش می گردد. نوع طراحی و آلیاژ به کار رفته در ساختار نازل واترجت صنعتی ، نقش مهمی در افزایش مقاومت و توان کاری آنها دارد.

آشنایی با انواع نازل دستگاه واترجت صنعتی

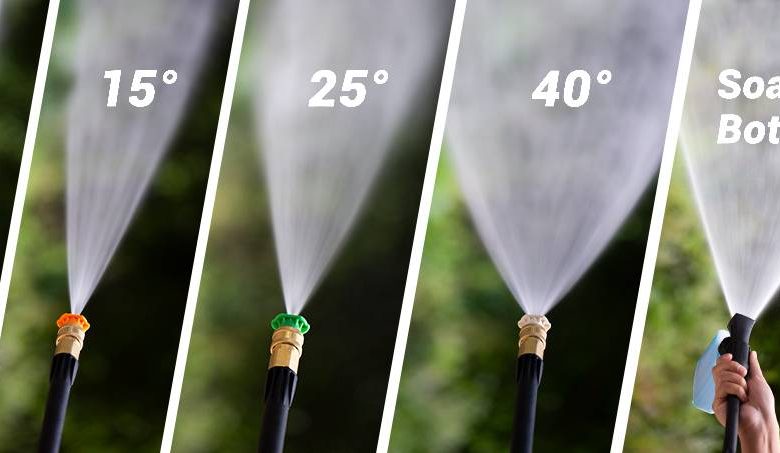

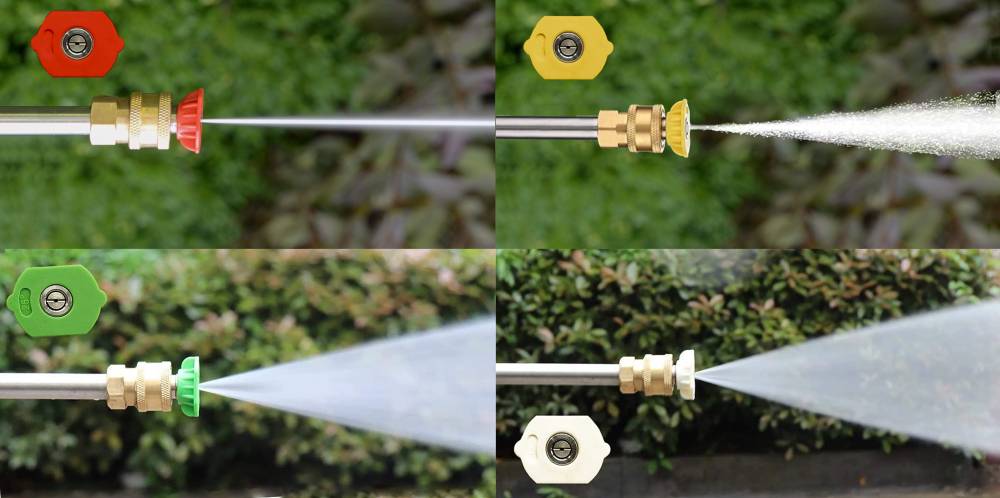

نازل های به کار رفته در دستگاه های واترجت صنعتی انواع مختلفی دارند که در ادامه به بررسی توانمندی هر یک از آنها در پاشش و جهت دهی به آب پر فشار خروجی از واترجت صنعتی، خواهیم پرداخت. بیشتر واترجت های صنعتی به نازل هایی با چهار یا پنج رنگ مجهز هستند. این رنگ بندی در انواع نازل کارواش صنعتی بر اساس زاویه پاشش آنها طبقه بندی شده است.

- قرمز ۰ درجه

- زرد ۱۵ درجه

- سبز ۲۵ درجه

- سفید ۴۰ درجه

- مشکی فشار پایین و پاشش ماده شوینده

نازل صفر درجه یا سوزنی کارواش دستی

نازل های صفر درجه یا قرمز رنگ در واترجت های صنعتی، که به واسطه کاهش حداکثری سطح مقطع دهانه خروجی جریان آب را به صورت متمرکز و خطی با فشار بسیار بالا بر سطح پاشش می کنند. این نازل ها در لایه برداری، برطرف کردن آلودگی های خشک شده و سر سخت، از سطوح مقاوم، سخت و فلزات مناسب می باشد. توجه داشته باشید که از این نازل ها بر روی سطوح چوب و سایر سطوح حساس استفاده نکنید. نازل های قرمز رنگ میتوانند خوردگی های شدیدی در دیوار ها و سطوح ایجاد کنند. پس تنها در صورت نیاز جدی از آنها استفاده نمایید.

فشار آب حاصل از این دسته تجهیزات جانبی کارواش صنعتی در صورت تماس با بدن میتواند باعث بروز آسیب های بسیار جدی شوند. در صورت نیاز به استفاده از آنها حتما از تجهیزات محافظتی و ایمنی مناسب استفاده نمایید. سطح مقطع بسیار کوچک در این نازل موجب کاهش زمان نظافت می گردد از این رو از این نازل ها برای از بین بردن لایه های عمیق آلودگی در مساحت های کم استفاده می شود. این انواع نازل کارواش صنعتی کاربرد گسترده ای در عملیات هایی چون تخریب بتن دارند.

نازل کاردکی یا تیغه ای در کارواش صنعتی

نازل های تیغه ای، آب را به صورت کاردکی با زاویه ای مشخص بر روی سطوح پاشش می نمایند. از آنجایی که سطح مقطع پاشش در این نازل ها بیشتر از نازل های سوزنی می باشد، این نازل ها سرعت بیشتری در نظافت دارند. اما قدرت پاشش با استفاده از انواع نازل کارواش تیغه ای در مقایسه با نازل های سوزنی کمتر بوده و از این رو برای نظافت های سطحی در محیط های وسیع به کار می روند. نازل های تیغه ای بر اساس زاویه پاشش انواع گوناگونی دارند اما متداول ترین آنها نازل های با زاویه پاشش ۱۵، ۲۵، ۳۰، ۴۰ و ۶۵ درجه می باشد. هر چه زاویه پاشش بیشتر شود، قدرت فشار پاشش کمتر شده و سرعت عملیات افزایش می یابد. از انواع این نازل میتوان به موارد زیر اشاره داشت:

نازل زرد رنگ

نازل های ۱۵ درجه در واترجت صنعتی با پاشش آب با زاویه ای باز تر، با ایجاد فشار پاشش مناسب آب در برطرف سازی آلودگی ها، زنگ زدگی فلزات، رنگ برداری، و آماده سازی سطوح پیش از رنگ زدن کاربرد فراوان دارد. در هنگام استفاده از این تجهیزات جانبی کارواش صنعتی، فاصله از سطوح مورد نظافت را رعایت نمایید. این نازل ها به راحتی آلودگی های چسبیده بر ماشین آلات کشاورزی و خودرو های سنگین را از بدنه و قطعات آن جدا می نماید.

نازل سبز رنگ واترجت صنعتی

نازل های سبز رنگ از رایج ترین نازل ها در واترجت صنعتی هستند. از این نازل ها برای نظافت اکثر سطوح میتواند به شکل کارآمد بهره گرفت. این نازل با پاشش آب با زاویه ای باز تر سطح بیشتری را با فشار مناسب شستشو میدهد. شستن سطوح و از برطرف سازی آلودگی و گل و لای که به شکل سطحی بر کفپوش ها جای گرفته اند با استفاده از نازل های سبز رنگ واترجت صنعتی به راحتی قابل نظافت خواهند بود. از این نازل برای نظافت سطوح کف، دیواره ها، بدنه خودرو، سطوح چوبی و بسیاری موارد دیگر استفاده نمود.

نازل سفید ۴۰ درجه واترجت صنعتی

نازل های سفید رنگ با زاویه پاشش نسبتا وسیع و ایجاد فشار پاشش مناسب، برای شستشوی سطوح شکننده همچون شیشه ها، گلدان ها، بدنه خودرو و سایر سطوح حساس قابل استفاده است. همچنین برای پاشش محلول های شوینده نیز میتوان از این دسته نازل واتر جت صنعتی استفاده نمود.

نازل متغیر واترجت صنعتی

نازل های متغییر دسته دیگری از انواع نازل کارواش صنعتی می باشند که امکان تغییر و انتخاب زاویه پاشش مناسب با نوع عملیات نظافتی را برای کاربر فراهم می نمایند. در این مدل از نازل ها، زاویه پاشش با چرخاندن سری نازل بین دو حد فاصل تعیین شده تغییر می کند. در برخی از مدل های نازل متغییر محدوده پاشش از صفر درجه آغاز شده و از این رو قابل استفاده به عنوان نازل های سوزنی می باشند.

نازل پاشش شوینده مشکی رنگ

نازل مشکی رنگ دارای پایین ترین فشار و بزرگترین روزنه پاشش است. این نازل سرعت پاشش را کاهش میدهد، که این امر باعث بالا رفتن فشار آب داخل شلنگ دستگاه واترجت صنعتی میشود. با استفاده از این نازل میتوان ماده شوینده را به صورت فوم و کف به آسانی بر سطوح مد نظر پاشش نمود.

نازل دوار واترجت صنعتی

عدم وجود همزمان قدرت پاشش بالا و سطح مقطع کاری وسیع در نازل های سوزنی و کاردکی موجب ابداع نازل های دوار گردید. نازل دوار در حقیقت یک نازل سوزنی می باشد که به طور پیوسته در حال چرخش می باشد. این نازل ها به واسطه داشتن سطح مقطع سوزنی توان بالایی در پاشش داشته و حرکت دورانی و پیوسته آن موجب افزایش سطح پاشش گردیده و از این کاربرد گسترده ای در نظافت لایه های عمیق آلودگی ها از محیط های وسیع دارند. مدل های پیشرفته نازل های دوار علاوه بر افزایش تعداد نقاط پاشش، امکان تنظیم سرعت چرخ را برای کاربر فراهم نموده اند.

نازل زمین شوی واترجت صنعتی

نازل زمین شوی از جمله تجهیزات جانبی شستشوی سطح زمین به شمار می آید که با مجهز شدن به دو یا چند نازل چرخشی، قادر به نظافت با کیفیت سطوح سنگ و بتنی است. استفاده از این دستگاه در نظافت و شستشوی انواع سطوح علاوه بر کاهش مصرف آب، با ایجاد تمرکز در پاشش آب، کیفیت بالای شستشو با دستگاه واترجت صنعتی را به دنبال خواهد داشت. این نازل با ابعاد و ویژگی های مختلف طراحی و تولید شده تا بتواند بسته به شرایط محیط انتخاب و استفاده گردد. افزایش سرعت نظافت با توجه به پهنای نظافت متفاوت این نوع نازل امکان پذیر است.

سایر تجهیزات ارائه شده برای واترجت های صنعتی

این دسته بندی بر اساس رنگ بخش ساده از نازل های مورد استفاده در واترجت های صنعتی هستند. با این حال طیف گسترده ای از انواع نازل کارواش صنعتی وجود دارند که با خرید و استفاده از آنها میتوان نظافت را به صورت حرفه ای و تخصصی تر صورت داد. از انواع این دسته نازل ها میتوان به نازل های توربو یا چرخشی، نازل های تغییر پذیر و نازل های نظافت تخصصی یا تجهیزات جانبی اشاره داشت. خرید و استفاده از واترجت با سامانه گرم کن با توجه به قیمت دستگاه کارواش آب گرم و کاربرد این تجهیزات در حین کار با واترجت صنعتی میتواند کیفیت نظافت سطوح و تجهیزات گوناگون را افزایش دهد. با خرید دستگاه کارواش صنعتی مناسب و استفاده از تجهیزات جانبی آن قادر به کسب کیفیت مطلوب از نظافت محیط مورد نظر خواهید بود.