راهنمای جامع نگهداری و چک لیست تعمیر و عیب یابی اسکرابر

اسکرابر ، یک دستگاه نظافتی کارآمد جهت شستشو و نظافت سطح زمین در محیط های مختلف می باشد. این دستگاه، برای شستشوی انواع سطوح و کفپوش ها اعم از سطوح بتنی، سرامیک، کفپوش های اپوکسی و .. طراحی شده است. برای کار با دستگاه کفشور صنعتی یا اسکرابر ، مطالعه دفترچه راهنما و رعایت نکات ایمنی دارای اهمیت است. این دستگاه های کفشوی که دارای عملکرد مشابهی هستند همگی دارای برس برای شستشو، تی لاستیکی برای جمع آوری آب و آلودگی ها، موتور مکنده برای مکش آب و همچنین دو مخزن مجزا برای آب تمیز و آب کثیف می باشد. با توجه به سادگی کارکرد این دستگاه ها، نیازی به آموزش های پیچیده نیست و تنها با رعایت چند نکته ساده و برنامه نگهداری دستگاه کفشوی می توان در بهبود عملکرد و افزایش طول عمر دستگاه کف شوی تاثیر گذار بود.

اهمیت و ضرورت نگهداری دستگاه کف شور صنعتی

استفاده از دستگاه نظافت مکانیزه برای شستشوی سطوح کف، به میزان زیادی در افزایش بازدهی و ارتقا کیفیت نظافت مجموعه تاثیر گذار است. از این رو، با بررسی و نگهداری صحیح از دستگاه های کفشوی می توان از بروز مشکلات ساده و از خرابی های جدی جلوگیری کرد. بررسی دستگاه قبل از هر بار استفاده و به صورت دوره ای میتواند از افت کیفیت و کارایی اسکرابر خودرویی یا دستی جلوگیری نماید. برخی از قطعات مانند برس، تی لاستیکی و باتری (در مدل های باتری دار) قطعات مصرفی هستند که باید پس از مدتی استفاده بررسی شده و در صورت نیاز تعویض شوند. زمان تعویض قطعات مصرفی بستگی به میزان استفاده، حجم آلودگی، جنس سطح و نحوه استفاده از دستگاه دارد.

علائم و نشانه های نیاز تعمیر و بازبینی دستگاه

در صورت مشاهده موارد زیر، باید با توجه به موارد و نکات ذکر شده، برای تعمیر و نگهداری دستگاه اقدامات لازم را انجام دهید.

کاهش کیفیت شستشو

عدم مراقبت از بخش های برس و تی مکش در دستگاه اسکرابر میتواند در کاهش کیفیت شستشوی سطح تاثیر گذار باشد. در این حالت دستگاه در ظاهر عملکرد درستی دارد، اما پس از شستشو لکه ها به خوبی رفع نشده اند. انتخاب مناسب برس، سالم بودن آن و فشار برس میتواند نقش مهمی در کیفیت کسب شده از نظافت داشته باشد. پس در صورتی که از برس ها و پدهای فرسوده که قدرت پاک کنندگی خوبی ندارند استفاده میکنید، باید سریعا برای تعویض آنها اقدام نمایید.

باقی ماندن لکه و رد روی سطح پس از شستشو

با پایان یافتن عمر لاستیک تی مکش، پس از شستشو، آب و آلودگی به خوبی از سطح جمع آوری نخواهد شد. این حالت نشان از فرارسیدن زمان تعویض لاستیک تی دارد. اما در صورت سلامت لاستیک ها و تراز بودن آنها، سیستم مکش باید مورد بررسی قرار گیرد که با تعمیر و نگهداری دستگاه کف شور صنعتی رفع خواهد شد. می توان قبل از اقدام به تعمیر دستگاه زمین شوی صنعتی از سلامت اتصالات شیلنگ مکش و تخلیه اطمینان حاصل نمود.

پاشش نامناسب آب و مواد شوینده

دستگاه کفشور با مجهز بودن با سامانه پاشش آب و مواد شوینده فرایند شستشو را با کیفیت بالا انجام خواهد داد. اما در صورتی که پاشش آب و یا محلول شوینده به صورت منظم از مخزن آب تمیز به روی برس و سطح انجام نشود، نظافت مطلوبی نتیجه کسب نخواهد شد. در این صورت باید بررسی اتصالات و شیلنگ آب تمیز و دریچه ها جهت اطمینان از عدم گرفتگی آنها صورت پذیرد. اگر مشکل با این بررسی ها برطرف نشد حتما باید از کارشناس متخصص راهنمایی گرفت.

اشکال در عملکرد کلی و روشن شدن دستگاه

حرکت دستگاه های کفشوی بستگی به وضعیت چرخ ها و برس و کارکرد صحیح باتری دارد. در صورت بروز مشکل در حرکت یا عملکرد دستگاه باید منبع تغذیه و باتری ها بررسی شوند و در صورت نبود مشکل دستگاه برای تعمیر موتور جلوبرنده به واحد تعمیرات ارسال گردد.

برای بررسی اولیه اسکرابر کاربرد می تواند مواردی را چک کند تا در صورت امکان آن ها را برطرف نماید. در این صورت نیز باید با شرکت تامین کننده تماس گرفته شود زیرا در صورت انجام برخی عملیات بر روی دستگاه ممکن است از گارانتی خارج شود.

دستگاه کف شوی صنعتی، برای شستشوی سطوح از آب و برس های خود استفاده می نماید. آب بطور یکنواخت بر روی سطح پاشیده شده و برس ها آلودگی ها را از بین می برند. در صورتیکه کاربر در استفاده از دستگاه، به نگهداری و مراقبت از بخش های مختلف آن اهمیت ندهد، طول عمر کفشوی کاهش می یابد. نگهداری مناسب زمین شوی، می تواند هزینه های تعویض برس ها و دیگر بخش ها را حذف نموده و موجب صرفه جویی در هزینه ها شود.

نکات سه گانه نگهداری دستگاه زمین شوی صنعتی

جدا از دسته بندی اسکرابر سرنشین دار یا زمین شوی دستی ، هنگام استفاده از دستگاه سه فرصت وجود دارد که از خرابی های پی در پی دستگاه کف شوی صنعتی جلوگیری شده و طول عمر مفید آن افزایش یابد. اصولی که کاربر قبل، حین و بعد از به کارگیری ماشین مکانیزه نظافتی انجام می دهد، تعیین کننده طول عمر دستگاه و مقدار نیاز آن به سرویس و خدمات، خواهد بود. افزایش طول عمر یک دستگاه نظافتی به معنای کاهش قابل توجه هزینه ها و صرفه جویی در وقت و انرژی می باشد و از همین رو نگهداری اسکرابر صنعتی یک فرآیند مهم در این راه به شمار می آید. در این چک لیست نگهداری اسکرابر سه مرحله و فرصت، بازبینی های پیش از استفاده از دستگاه، نکات حین کاربرد دستگاه و فعالیت های مراقبت و نگهداری بعد از شستشوی سطوح با دستگاه گنجانده شده است. با رعایت این برنامه نگهداری دستگاه کفشوی میتوانید در صورت بروز هرگونه مشکل در فعالیت دستگاه، از خرابی های بیشتر آن جلوگیری نمایید.

نگهداری های قبل از استفاده اسکرابر

پیش از به کارگیری زمین شوی صنعتی، مواردی وجود دارد که با رعایت آن قادر به افزایش عمر و کیفیت کار دستگاه خواهید بود. به عنوان مثال اگر محیط مملو از گرد و خاک و زباله باشد، پیش از استفاده از دستگاه، ابتدا ضایعات و آلودگی های درشت را جمع آوری نمایید. عدم تماس این آلودگی های درشت با بخش های حساس دستگاه مانند برس، تی، فیلتر، شلنگ ها و عدم ته نشینی آنها در مخزن آب کثیف راهکاری عالی برای افزایش طول عمر دستگاه است.

بررسی سلامت تجهیزات اسکرابر مانند برس ها، اتصالات، سالم بودن فیلتر ها و عدم وجود ترک و شکستگی در لاستیک تی مکش، از دیگر مواردی است که پیش از آغاز فرایند نظافت میتواند در بهبود کیفیت نظافت تاثیر چشمگیر بگذارد.

نگهداری های حین استفاده اسکرابر

زمانی که شما مراقبت ها و نکات نگهداری اسکرابر قبل از استفاده را به خوبی در نظر گرفته باشید، کمتر احتمال دارد حین کار با دستگاه کف شوی صنعتی به مشکل خاص برخورد کنید. با این حال کارکردن با دستگاه در بازه های زمانی مناسب و خودداری از اعمال فشار کاری بالا بر دستگاه، کارکرد این دستگاه نظافت مکانیزه را بهینه خواهد نمود. این توصیه برای نگهداری اسکرابر صنعتی هم مفید خواهد بود؛ یکی از بهترین راه ها برای اطمینان از عملکرد خوب دستگاه کف شور صنعتی توجه زیاد در زمان کارکرد آن می باشد.

زمانی که کاربر عملکرد دستگاه خود را بشناسد، در صورت شنیدن صدای بلند یا نامتعارف از موتور مکنده و یا مشاهده رگه های آب روی زمین، به سرعت متوجه خواهد شد که مشکلی در اجزای اسکرابر صنعتی به وجود آمده است. مثلاً صدای بلند موتور مکنده نشان دهنده خرابی آن بوده و یا باقی ماندن رد آب روی زمین حاکی از خرابی لاستیک تی مکش یا به طور کلی سیستم مکش است. بنابراین هنگامی که کاربر به کار با دستگاه می پردازد، همواره باید عملکرد کلی اسکرابر صنعتی و هم چنین اجزای آن را در نظر داشته باشد.

نگهداری های بعد از استفاده اسکرابر

هر دستگاهی برای داشتن دوام و طول عمر بیشتر نیاز به مراقبت و نگهداری دارد. توجه به نکات نگهداری پس از استفاده از دستگاه اسکرابر صنعتی میتواند از خرابی و اشکالات دستگاه در طولانی مدت پیشگیری نماید. با تعمیر و نگهداری اسکرابر صنعتی به شکل صحیح و اصولی، این دستگاه سال های زیادی به عنوان یک ابزار کارآمد عمل خواهد کرد. بخش عمده ای از عملیات حفظ و نگهداری بعد از شستشوی روزانه با دستگاه انجام می پذیرد. داشتن یک چک لیست نگهداری دستگاه کفشور و عمل کردن مطابق آن می تواند مفید و مؤثر باشد.

جداسازی قطعاتی مانند برس و شلنگ ها را به سادگی امکان پذیر بوده و میتواند پس از استفاده از دستگاه به راحتی مورد نظافت قرار گرفته و دوباره نصب گردند. تمیز کردن فیلتر ها، تخلیه و شستشوی مخازن آب تمیز و آلوده دستگاه، شارژ مجدد باتری دستگاه به طور کامل و از سایر بخش های لازم و مهم جهت نگهداری و مراقبت هستند. دیگر بخش های دستگاه نیز نیاز به بررسی های دوره ای و تعویض در صورت بروز خرابی دارند. باقی ماندن آب در مخازن در بلند مدت سبب بر جای گذاشتن رسوب و کپک می شود که میتواند مشکل ساز شود. بعد از تخلیه مخزن آب کثیف و بررسی شلنگ ها، تا خشک شدن کامل مخزن باید درب آن باز باشد.

مراقبت بخش های مختلف دستگاه اسکرابر صنعتی

دستگاه اسکرابر متشکل از بخش های مختلفی است. داشتن چک لیست نگهداری اسکرابر و مراقبت از اجزای آن، کارکرد بهینه دستگاه حین نظافت را تضمین می نماید:

نگهداری برس کف شوی صنعتی

سیستم برس زنی اسکرابر از یک یا دو برس تشکیل شده که با سرعت بالا بر روی سطح زمین به چرخش در می آیند. با چرخش برس ها، آلودگی ها به خوبی از سطح جدا می شوند. البته این امر تا حد زیادی با انتخاب برس متناسب با جنس سطح میسر می شود. معمولا پرز ها، موها و ذرات ریز در حین نظافت در برس کف شوی صنعتی به دام می افتند که این امر در انجام عملیات شستشو اختلال ایجاد می نماید. با جذب شدن این ذرات در ساختار برس، نظافت با کیفیت کامل انجام نشده و طول عمر برس ها نیز کاهش می یابد. بنابراین اپراتور کف شوی باید بعد از هر مرحله نظافت، برس ها را تمیز نماید. این کار همچنین در کاهش هزینه های مربوط به تعویض برس تاثیر گذار است.

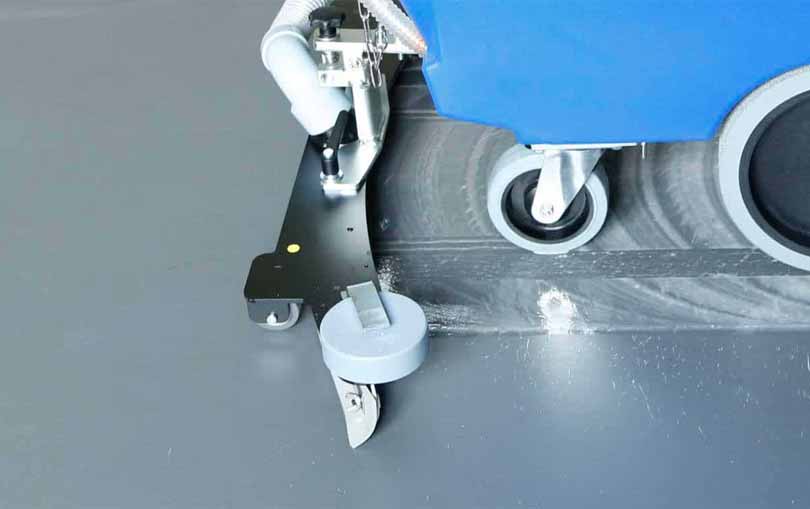

نگهداری تی خشک کن کف شوی صنعتی

یکی از ویژگی های مهم دستگاه های زمین شوی ، جمع آوری آب آلوده و خشک کردن سطح زمین می باشد. این امر توسط تی خشک کن و سیستم مکش کف شور صورت می پذیرد. تی اسکرابر در حین جمع آوری آب آلوده می تواند به مواد و ذراتی آغشته شود. نتیجه این امر اختلال در امر جمع آوری آب آلوده و انتشار آن به بخش های دیگر می شود. همچنین ممکن است بعضی ذرات با کشیده شدن خود بر روی سطح زمین، موجب ایجاد خراش بر روی سطح شوند. بنابراین لازم است اپراتور بعد از هر روز کاری، تی خشک کن کف شوی را تمیز و عاری از آلودگی نماید. این امر به افزایش طول عمر لاستیک تی نیز منجر خواهد شد.

نگهداری باتری کف شوی صنعتی

زمین شوی باتری دار که به صورت دستی یا خودرویی تولید می شوند، از باتری جهت تامین منبع تغذیه خود و چرخش برس ها بهره می برند. بدون شک باتری یکی از اصلی ترین قسمت ها در این دسته اسکرابر های باتری دار و شارژی است. نوع باتری مورد استفاده در اسکرابر ها ژلی بوده که به تعمیر و نگهداری خاصی نیاز ندارد، هرچند رعایت نکاتی می تواند در افزایش طول عمر آن تاثیر گذار باشد. انواع باتری اسکرابر به عنوان قلب دستگاه در صورتی که به درستی و براساس دستورالعمل های ویژه مورد استفاده و مراقبت قرار نگیرد در کوتاه مدت دچار آسیب خواهد شد، اما برخی مراقبت ها در مدل های مختلف اسکرابر باتری دار یکسان می باشد. در ادامه به بررسی این موارد پرداخته می شود.

- به هنگام سرویس باتری حتما از دستکش استفاده کنید و از دست زدن به اسید باتری در هر صورت خودداری نمایید.

- همیشه از مسیر تعیین شده برای شارژ اسکرابر باطری دار پیروی کنید.

- قسمت ترمینال و سری باتری ها را از خوردگی دور نگه دارید. استفاده از محلول جوش شیرین به منظور دور نگه داشتن باتری از خوردگی بسیار موثر می باشد. نکته مهم: نباید اجازه دهید که ترکیب جوش شیرین وارد باتری گردد.

- از یک برس سیمی به همراه محلول جوش شیرین به منظور تمیز کردن اتصالات باتری استفاده کنید.

- یکی از مهم ترین بخش ها در نگه داری و مراقبت از دستگاه اسکرابر توجه به سالم بودن تمامی اتصالات و ترمینال های باتری و جایگزینی اتصالات معیوب بسیار ضروری است.

- محل شارژ باتری نیز می بایست محلی با دمای حداکثر ۳۰ درجه و بدون رطوبت و خاک باشد. همچنین تخلیه کامل باتری در بازه های زمانی که در دفترچه کفشوی آمده، می تواند در افزایش طول عمر آن موثر باشد.

نگهداری بخش های دیگر دستگاه

به جز بخش های مهم ذکر شده در این مقاله، قسمت های دیگری چون اتصالات و قطعات و کناره های دستگاه نیازمند مراقبت می باشد. تسلط بر محیط پیرامون و مراقبت از موانع، از آسیب به دستگاه جلوگیری می نماید. روغن کاری اتصالات و قطعات نیز در عملکرد بهتر کف شوی تاثیر چشم گیری دارد. در ادامه یک برنامه روزانه و ماهانه برای مراقبت و نگهداری دوره ای دستگاه اسکرابر مطرح میکنیم. با استفاده از این برنامه نگهداری دستگاه کفشوی و عیب یابی میتوانید به شکل مطلوب از سلامت دستگاه اسکرابر صنعتی خود اطمینان حاصل نمایید.

نظافت دوره ای دستگاه اسکرابر صنعتی

به دلیل اینکه در بسیاری از مراکز تجاری،درمانی، اداری و صنایع استفاده گسترده اسکرابر صنعتی به صورت مداوم، نیاز مراقبت و نگهداری روزانه و ماهانه و چک لیست نگهداری اسکرابر میتواند به میزان زیادی در افزایش ماندگاری و کاهش نیاز تعمیرات اساسی دستگاه موثر باشد.

نگه داری و مراقبت روزانه

دستورالعمل و چک لیست نگهداری دستگاه کفشور به صورت روزانه را میتوانید با توجه به تصویر زیر به طور دقیق و مطلوب انجام دهید.

نگهداری و مراقبت ماهانه

پیش از انجام هرگونه عملیات سرویس لازم است تا دستگاه خاموش شده و باتری از اتصال خارج گردد. سپس می توان اقدامات لازم برای نگه داری و مراقبت از دستگاه کف شور صنعتی را انجام داد. برخی از اقدامات به شرح زیر می باشد:

- زمین شوی صنعتی را به منظور رفع هرگونه نشتی و محکم کردن پیچ و مهره ها بررسی نمایید.

- تمامی اتصالات و نقاط محوری نیازمند روانکاری با اسپری سیلکون و یا روغن های باکیفیت هستند.

- دستگاه را بر روی یک زهکشی قرار داده و مخزن آب تمیز را با استفاده سه گالن آب ولرم و مواد شوینده قلیایی مناسب پر نمایید. دستگاه را به مدت ۴۵ ثانیه روشن کرده و حرکت دهید. سپس دستگاه را خاموش کرده و اجازه دهید تا محلول به مدت یک شبانه روز در داخل مخزن باقی بماند. روز بعد می توانید محلول را تخلیه کرده و مخزن آب تمیز دستگاه را با آب تمیز پر کنید.

اهمیت چک لیست نگهداری اسکرابر صنعتی

داشتن برنامه و چک لیست نگهداری دستگاه کفشور و مراقبت از دستگاه زمین شوی صنعتی و دنبال کردن آن که از سوی کارخانه سازنده یا نمایندگی های معتبر اعلام شده است، می تواند بهترین راهکار برای افزایش طول عمر و بازیابی کارایی دستگاه باشد. با توجه به قیمت دستگاه زمین شوی برقی و باطری دار مراقبت، عیب یابی و نگهداری بهینه از آن ارزش دستگاه کفشوی را حفظ می کند. با اجرای عملیات حفظ و نگهداری دستگاه زمین شوی صنعتی یعنی سه مرحله ذکر شده، می توان اطمینان حاصل نمود که اسکرابر در بهینه ترین حالت ممکن قرار دارد و از تحمیل هزینه های اضافه و بیهوده برای تعمیرات دستگاه جلوگیری خواهد شد.

توجه داشته باشید که برخی موارد و مشکلات دستگاه اسکرابر به سادگی قابل برطرف شدن نیست. در صورت مواجه شدن با چنین مشکلات و مواردی حتما با مرکز پشتیبانی و خدمات پس از فروش تماس بگیرید تا کارشناسان، شما را در جهت رفع ایراد دستگاه راهنمایی کنند.

جدول راهنمای عیب یابی و نگهداری دستگاه کف شوی صنعتی

| دانلود راهنمای عیب یابی و نگهداری دستگاه کف شوی صنعتی | ||

| مدل دستگاه | تصویر | دفترچه راهنمای نگهداری و عیب یابی |

| اسکرابر RA43B20 |  |

دانلود |

| اسکرابر RA55BM40 |  |

دانلود |

| اسکرابر ARA66BM70 |  |

دانلود |

| اسکرابر ARA 80BM 100 |  |

دانلود |

| اسکرابر ARA 100BM 150 |  |

دانلود |

| اسکرابر ایرانی IR55B40 |  |

دانلود |

| اسکرابر ایرانی IR55K40 |  |

دانلود |

| اسکرابر دستی T2 |  |

دانلود |

| اسکرابر دستی T5 |  |

دانلود |

| اسکرابر خودرویی T12 |  |

دانلود |

| اسکرابر دستی T300e |  |

دانلود |

| اسکرابر دستی T500e |  |

دانلود |

| اسکرابر ARA 85BM 120 |  |

دانلود |

| اسکرابر RA55BM60 |  |

دانلود |

| اسکرابر RA66BM60 |  |

دانلود |

| اسکرابر خودرویی T16 |  |

دانلود |

| اسکرابر خودرویی T20 |  |

دانلود |

ما یه اسکرابر دستی داریم که کامل آب رو جمع نمیکنه، رد آب میندازه رو زمین. باید چیکارش کنم؟ اوایل خیلی خوب کار میکرد اما الان مکش نداره انگار درست جمع نمیکنه

سلام وقت بخیر

تی لاستیکی مکش اسکرابر بعد از مدت زمان کارکرد طولانی برای حفظ کیفیت نظافت نیاز به تعویش دارد. برای خرید تجهیزات جانبی اسکرابر از جمله لاستیک تی مکش، میتوانید با شماره تلفن ۸۷۱۸۴-۰۲۱ تماس گرفته و با استفاده از مشاوره خرید، تجهیزات جانبی مناسب دستگاه نظافت صنعتی خود را خریداری کنید.